|

|

|

|

|

|

|

|

The

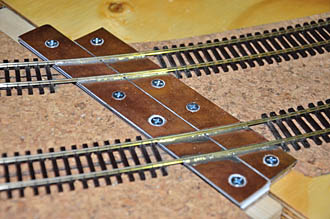

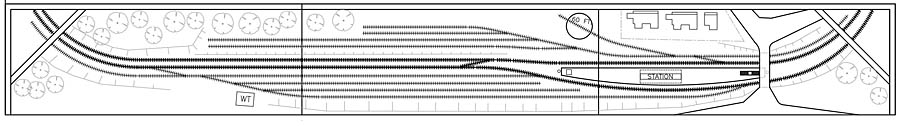

track and point work on the front boards are laid in Peco code

83. The track is

laid upon 17mm

plywood sub road bed and 6mm cork.

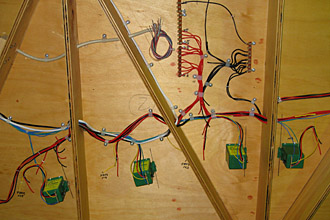

The points are actuated using Tortoise point motors. The layout is designed to be run with either DC or DCC control. Joints across the base boards are were done using PCB strips and PCB sleepers. Rail is laid over the joint, the PCB compnenets fabricated, soldered and up then the track is cut using a small saw. |

|

|

|

| subroad bed cutting 10-10-09 |

laying cork 17-10-09 |

track laying 29-12-09 |

|

|

|

| track laying 08-01-10 |

track laying 29-12-09 | track laying 08-01-10 |

|

|

|

| PCB transition to the fiddle yard |

PCB transition between front boards |

track cutting |

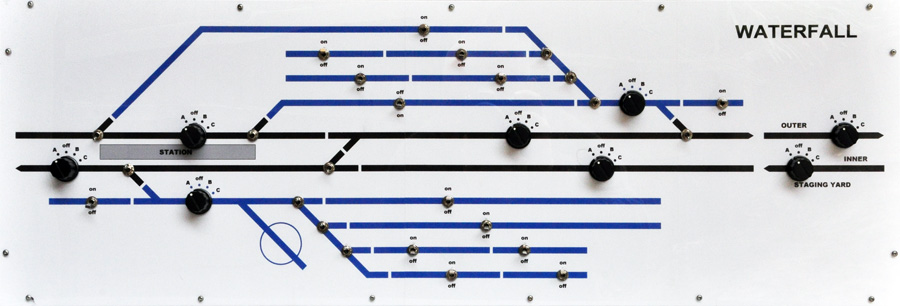

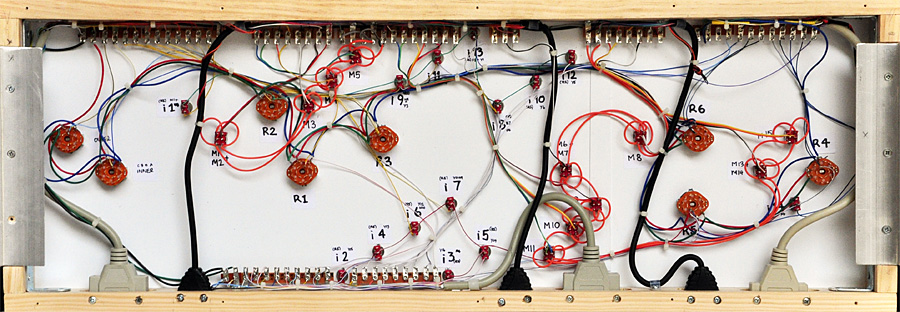

| The

layout is designed to be run with either DC or DCC control. The layout

is common wired. There are three DC cabs. Point control goes up to the

control panel via DB15 plugs and track power via DB25

plugs, one from each board. When running with DCC the DB25 plugs are

disconnected from the control panel and the DCC system connected up to

the front boards. |

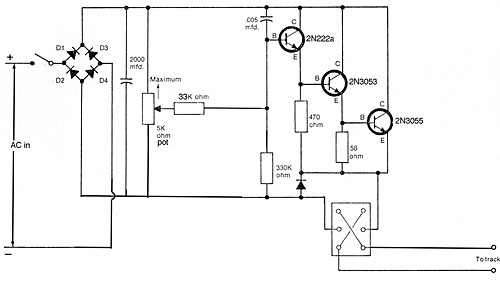

| The

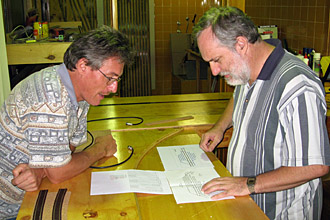

DC controllers for the layout were constructed by the Monday Modelling group. The basic

circuit used is a hardy three transistor design from "Practical

Projects

for Model Railroaders" Kalmbach books, 1974. |

|

|

|

|

|

|

home

I about us

I find

us I layouts

I models

I calendar

I links